In this chapter of our web series, we would like to introduce you to the fascinating world of 3D printing technology and explain why we chose PLA as our material of choice.

The technology of 3D printers

We utilise the latest FDM printing technology to turn our creative visions into reality. Our fleet comprises six FDM printers, which are known for their versatility and user-friendliness. But what does that actually mean?

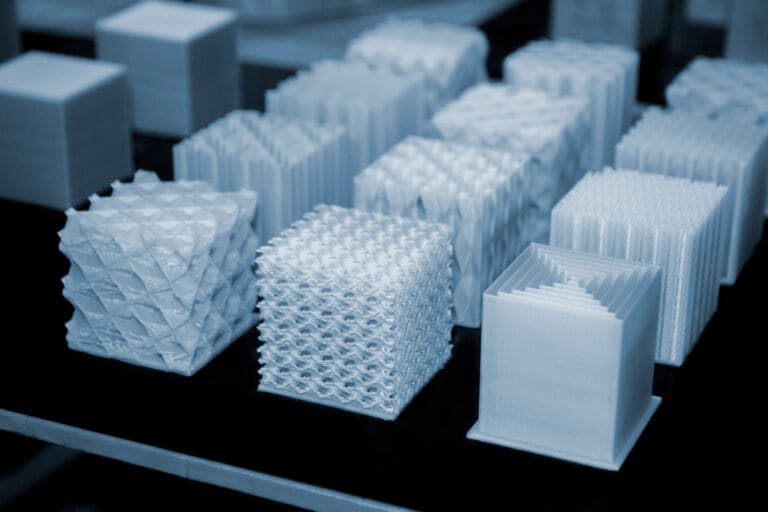

FDM printers work according to the layer construction method, in which the material, usually a thermoplastic, is applied in layers. These printers are particularly suitable for the production of larger objects and are our first choice for sustainable production methods due to their efficiency and precision.

One fascinating aspect of FDM technology is its versatility and scalability. The FDM process is now also used in house construction. Large FDM printers can print entire buildings layer by layer from special concrete mixtures. This innovative application shows just how powerful and flexible FDM technology is, as it can produce not only smaller, highly detailed objects, but also massive structures efficiently and cost-effectively. This technology is revolutionising the construction process, enabling more sustainable building methods and significantly reducing material waste.

However, our printers are also able to print complex models, not houses but on a small scale and with colour changes in the middle of the print. This allows us to realise particularly unusual and creative shapes that give every product a unique touch.

Our printers can process a wide range of materials, including more technically demanding filaments with carbon content. However, we have deliberately opted for PLA (polylactide) for our products.

for our products.

The material: PLA

PLA is a thermoplastic material made from renewable raw materials such as corn starch. It has a number of properties that make it an excellent choice for sustainable 3D printing projects.

- Biodegradable: PLA is 100% industrially biodegradable and therefore more environmentally friendly than many other plastics.

- Sustainable:

As PLA is made from plant material, it is a renewable resource. - Safe and non-toxic: PLA is free from harmful chemicals and is therefore safe for use in households and offices.

By combining innovative 3D printing technology and sustainable materials such as PLA, we are able to produce functionally appealing and ecologically responsible products. This approach shows that cutting-edge technology and environmental awareness can go hand in hand.

What happens next?

But our journey doesn’t end here! In the next chapter, we dive deep into the exciting world of brand development. How do you create a brand

brand that combines creativity, innovation and sustainability

in a nutshell? And how do you find the perfect shop system to turn this vision into reality? Stay tuned to find out how we overcome these challenges and continue our journey from pixel to product.